The enVision Math Grade 5 Workbook Answer Key PDF is a comprehensive resource designed to support students and educators. It provides detailed explanations and step-by-step solutions for all topics‚ ensuring a deep understanding of mathematical concepts. The workbook is structured into two volumes‚ covering essential skills like place value‚ decimals‚ multiplication‚ and division. With its clear format and thorough answers‚ it helps students build confidence and improve their math proficiency effectively.

Structure of the Workbook

The enVision Math Grade 5 Workbook is divided into two volumes‚ each focusing on specific mathematical concepts. Volume 1 covers foundational topics like place value and decimals‚ while Volume 2 delves into fractions‚ geometry‚ and advanced operations‚ providing a structured approach to learning.

Volume 1

Volume 1 of the enVision Math Grade 5 Workbook focuses on foundational mathematical concepts‚ providing a solid base for further learning. It covers essential topics such as place value‚ adding and subtracting decimals‚ and fluently multiplying multi-digit whole numbers. The workbook is designed to help students grasp these critical skills through engaging exercises and real-world applications. Each lesson is supported by detailed explanations and step-by-step solutions in the answer key‚ ensuring students can review and understand their work. Volume 1 also introduces strategies for dividing whole numbers and decimals‚ preparing students for more complex operations in later volumes. With its clear structure and comprehensive coverage‚ Volume 1 sets the stage for mathematical success in higher grades.

Volume 2

Volume 2 of the enVision Math Grade 5 Workbook builds on the foundational skills introduced in Volume 1‚ focusing on more advanced mathematical concepts. It delves into topics such as applying understanding of multiplication to multiply fractions‚ dividing fractions‚ and representing and interpreting data. Additionally‚ it covers geometric measurement and classifying two-dimensional figures. The workbook includes detailed explanations and step-by-step solutions in the answer key‚ helping students master complex operations and apply their knowledge confidently. Volume 2 is designed to deepen problem-solving skills and prepare students for higher-grade mathematics. With its comprehensive coverage and interactive approach‚ it serves as an invaluable resource for both classroom and independent learning.

Key Features

The enVision Math Grade 5 Workbook Answer Key PDF offers detailed explanations and step-by-step solutions for all exercises. It provides clear guidance‚ helping students understand complex concepts and improve problem-solving skills effectively.

Detailed Explanations

The enVision Math Grade 5 Workbook Answer Key PDF delivers thorough explanations for each problem‚ breaking down complex concepts into manageable parts. By providing a clear understanding of mathematical principles‚ it equips students with the tools needed to tackle challenging questions confidently. Every step of the solution process is meticulously outlined‚ ensuring that learners grasp both the “how” and the “why” behind each math problem. This feature is particularly beneficial for visual and kinesthetic learners‚ as it mimics the guidance of a classroom instructor. The detailed explanations also serve as an excellent resource for parents and educators seeking to support students outside of school. This comprehensive approach fosters a deeper understanding and appreciation of mathematics‚ making it an invaluable study aid for fifth graders.

Step-by-Step Solutions

The enVision Math Grade 5 Workbook Answer Key PDF offers step-by-step solutions for every problem‚ guiding students through the problem-solving process with clarity. Each solution is methodically broken down‚ ensuring that learners can follow along and understand each mathematical operation. This structured approach helps students identify potential pitfalls and master techniques for tackling complex problems. By aligning the solutions with the workbook’s exercises‚ it reinforces learning and builds problem-solving confidence. The step-by-step format is particularly useful for students who need additional support or those aiming to excel in math. It also serves as a valuable tool for parents and educators to track progress and provide targeted assistance‚ making it an essential resource for successful math education at the fifth-grade level.

Topics Covered

The workbook covers essential math concepts‚ including place value‚ decimals‚ multiplication‚ and division of whole numbers and decimals. It also explores geometry and data interpretation skills.

Place Value

The enVision Math Grade 5 Workbook Answer Key PDF thoroughly covers place value‚ helping students understand how digits represent different values in numbers. It includes exercises on reading and writing numbers in standard and expanded forms‚ as well as identifying the value of each digit. The workbook provides detailed solutions for problems involving place value charts and models‚ ensuring students grasp the fundamental concepts needed for higher-level math operations. Step-by-step explanations and visual models guide learners through complex topics‚ making the understanding of place value both comprehensive and engaging. This section is crucial for building a strong foundation in numeration and prepares students for more advanced topics like decimals and multi-digit calculations.

Decimals

The enVision Math Grade 5 Workbook Answer Key PDF provides in-depth coverage of decimals‚ helping students master essential skills. It includes detailed explanations for adding‚ subtracting‚ multiplying‚ and dividing decimals‚ as well as rounding numbers to the nearest tenth or hundredth. The workbook offers step-by-step solutions to problems involving decimal models and strategies‚ ensuring students understand how to apply these concepts in real-world scenarios. Topics such as comparing decimals‚ placing them on number lines‚ and converting between fractions and decimals are also addressed. With clear answers and visual models‚ the workbook empowers students to tackle decimal operations with confidence and accuracy‚ building a solid foundation for advanced math topics.

How to Access the PDF

To access the enVision Math Grade 5 Workbook Answer Key PDF‚ visit the official Pearson Education website or authorized educational platforms like StudyHub.vip. Create an account or log in to access resources. You can also explore Teachers Pay Teachers (TpT) for shared resources by educators. Additionally‚ check your school’s website or consult with your teacher for direct links or downloadable copies. Ensure you obtain the PDF from reliable sources to guarantee authenticity and completeness.

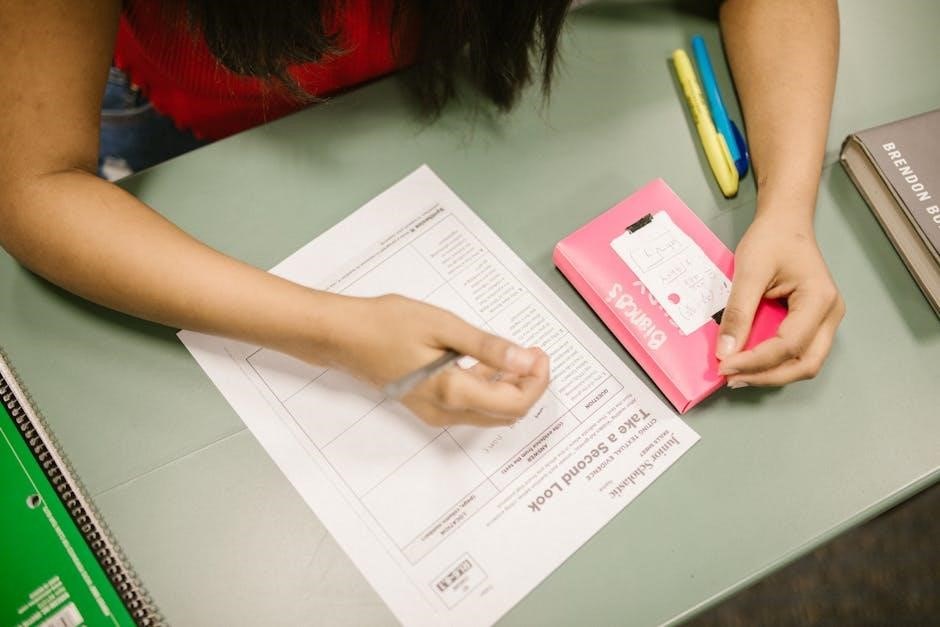

Tips for Effective Use

To maximize the benefits of the enVision Math Grade 5 Workbook Answer Key PDF‚ use it as a study companion alongside your workbook. Attempt problems independently before referencing the answer key to reinforce learning. Review detailed explanations to understand problem-solving strategies and identify common mistakes. Highlight key steps in the solutions to focus on critical concepts. Use the answer key for test preparation by practicing past topics and reviewing challenging areas. Encourage a routine of checking answers weekly to track progress and improve accuracy. By integrating the answer key into your study routine‚ you can enhance your math skills and build confidence in tackling complex problems effectively.

Common Challenges

Students using the enVision Math Grade 5 Workbook Answer Key PDF may face challenges with understanding place value‚ decimals‚ and multi-digit operations. Fractions and geometry concepts often require additional practice; To overcome these‚ review detailed explanations in the answer key to clarify complex topics. Focus on step-by-step solutions to identify where errors occur. Regularly practicing problem types that are difficult helps build mastery. Use the answer key to check work and ensure accuracy. Encourage breaking problems into smaller steps and seeking help when needed. By addressing these challenges systematically‚ students can improve their math skills and gain confidence in tackling difficult problems effectively.

Additional Resources

Beyond the enVision Math Grade 5 Workbook Answer Key PDF‚ students can access additional resources to enhance their learning. Interactive workbooks like StudyHub.vip offer digital practice options‚ while video tutorials and mobile apps provide visual and hands-on experiences. Pearson Education’s official website features supplementary materials‚ including lesson plans and games. For further practice‚ enVision Mathematics Additional Practice Pages are available‚ covering topics like place value and decimals. Online forums and educational websites also offer tips and solutions for challenging problems. These resources ensure students have multiple ways to engage with the material and deepen their understanding of math concepts.